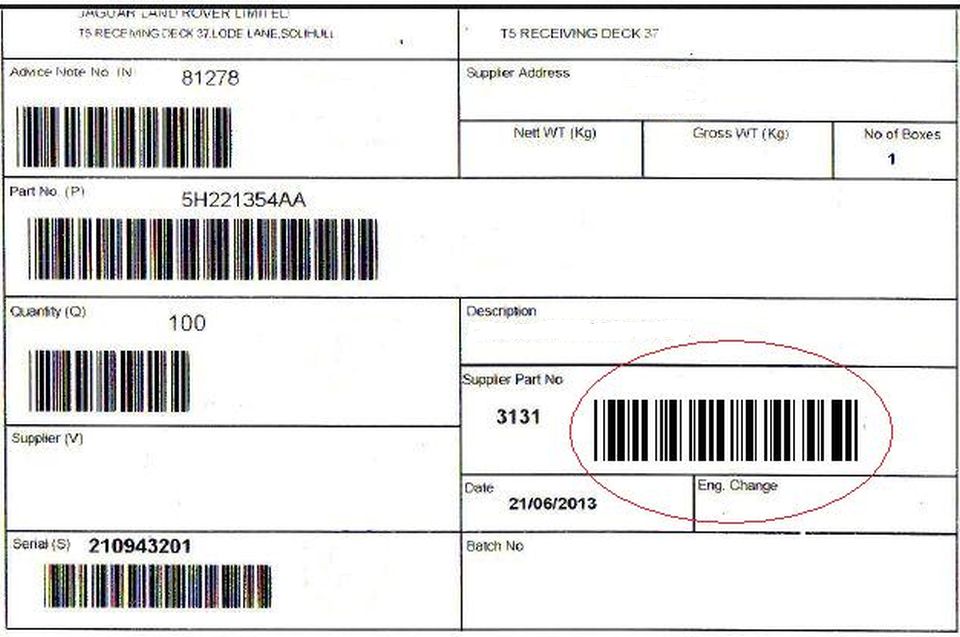

Boxes in warehouses and despatch areas look alike. Scanning a serial number confirms you are picking the right one.

Jaguar Land Rover demand components arrive just in time in assembly order. As do all other vehicle makers.

One manufacturer set up a team to analyse their despatch process. The project team found it risked leading to mistakes and fines. They asked us for a solution as they knew Codeway had worked with other Tier 1 parts suppliers.

The problem

To define the problem the team had worked with supervisors and staff. Their task was to match the products in each consignment with the advice note. To do that without fail they needed barcode scanners linked to the ERP system.

There were three potential mistakes:

- Invalid pallet labels,

- Incorrect products or quantities on the pallet,

- Incorrect products and quantities in the consignmment.

To guarantee 100% accurate deliveries to the assembly lines company had to match every item, box and container to the order.

The key to the solution was to match the product code on the pallet to the product code on the boxes.

The solution

The elements of the system Codeway installed were:

- Mobile scanners linked by WiFi to a server and the ERP system.

- Mobile software to guide the user and capture data.

- Server software to query the ERP system, produce reports and keep a log.

Codetrack process

- Secure logon: users enter their ERP credentials on the mobile unit.

- Delivery number: scan the delivery number and retrieve delivery details.

- Serialisation: scan and check the serial number on the box label.

- Part numbers: scan the part number on the box label and match to the pallet label.

- Part alarm: notify a supervisor when part numbers do not match.

- Quantity alarm: notify supervisor when quantities are incorrect.

- Log: for full traceability at box level and reports.

The software has various cross checks to prevent errors and shortcuts.

Results

Codetrack has alerted the supervisor to an error on several occasions.To date Jaguar Land Rover have not reported an error.

Productivity in despatch increased by around 20% increased by eliminating paperwork. There was also a reduction time spent handling exceptions which the system either prevented or detected.

Following this success the company commissioned Codeway to develop a material supply system. Its purpose was to ensure polymeric compound suppliers would always deliver sufficient material for the company to meet JLR's rolling assembly schedules.

Related Applications