EU good manufacturing and distribution practices apply to generic drugs including Annex 11 for computerised systems.

Pharmaceuticals come in many pack sizes. Batch numbers and expiry dates must be tracked.

A generic drugs manufacturer had outgrown paper based fulfilment. Many branded product distributors have similar operations. Except for mandatory controls like pick checks, stock rotation by expiry date and batch traceability.

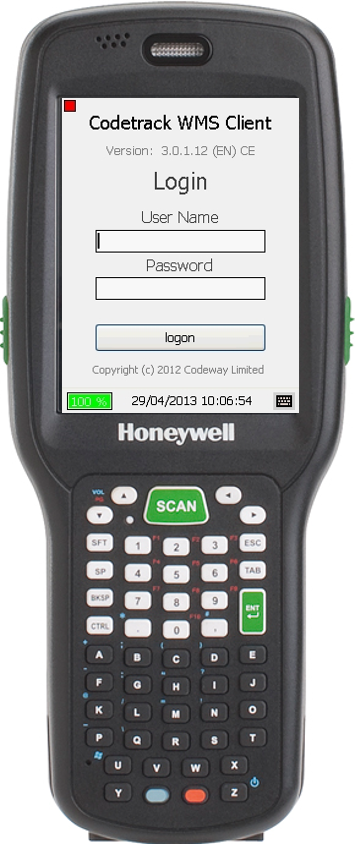

Codeway set up Codetrack to meet the requirements. The key points in the project apply to most mobile data systems: user screens, database fields, ERP data exchange.

Master data

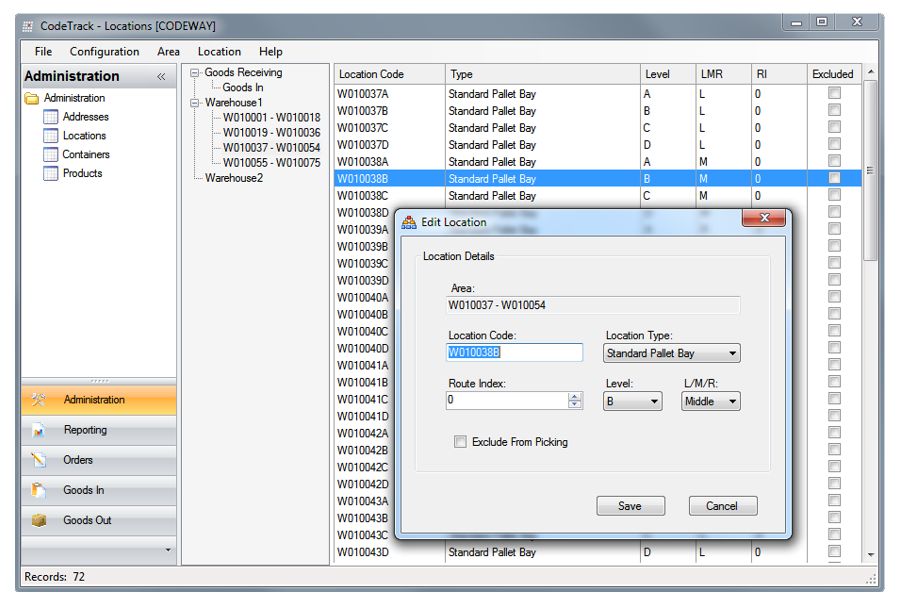

Set up and manage warehouses and locations. Define types of location and their dimensions.

Set up and manage warehouses and locations. Define types of location and their dimensions.

Codetrack holds five type of master data:

- Users (individuals, groups, permissions)

- Partners (customers, suppliers: names, addresses)

- Products (codes, details)

- Locations (warehouses, locations)

- Containers (category, type: e.g. 'PALLET', 'EURO')

Batch control is rigid. The products in storage locations are in containers or pallets, both uniquely numbered.

Configuration options include: label printers · document printers · import–export · email alerts · status colours: pending, in progress, paused, complete.

Goods in

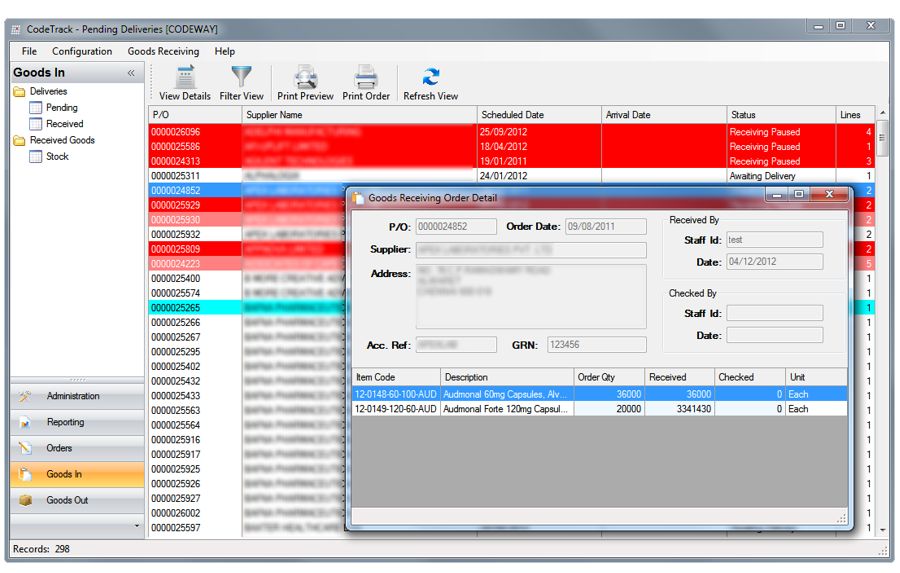

The pending deliveries screen shows the status of deliveries and scheduled deliveries.

The pending deliveries screen shows the status of deliveries and scheduled deliveries.

Supervisors use the pending deliveries screen to check progress and perform operations at goods-in.

Note: Codetrack gets purchase and sales order data from the ERP system.

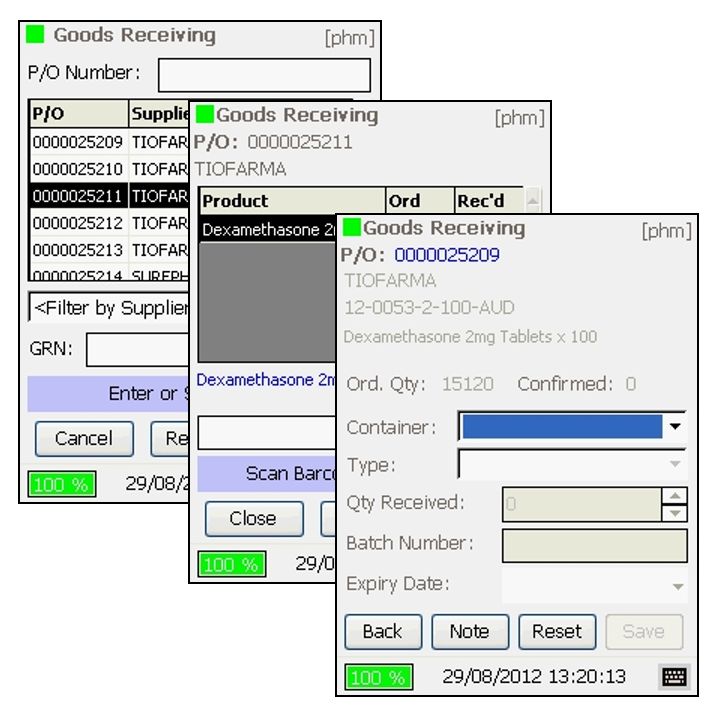

Goods receiving screens

Goods receiving screens

Simple screens guide mobile users through receiving: select purchase order · scan and receive · check delivery: go back or confirm.

Pick

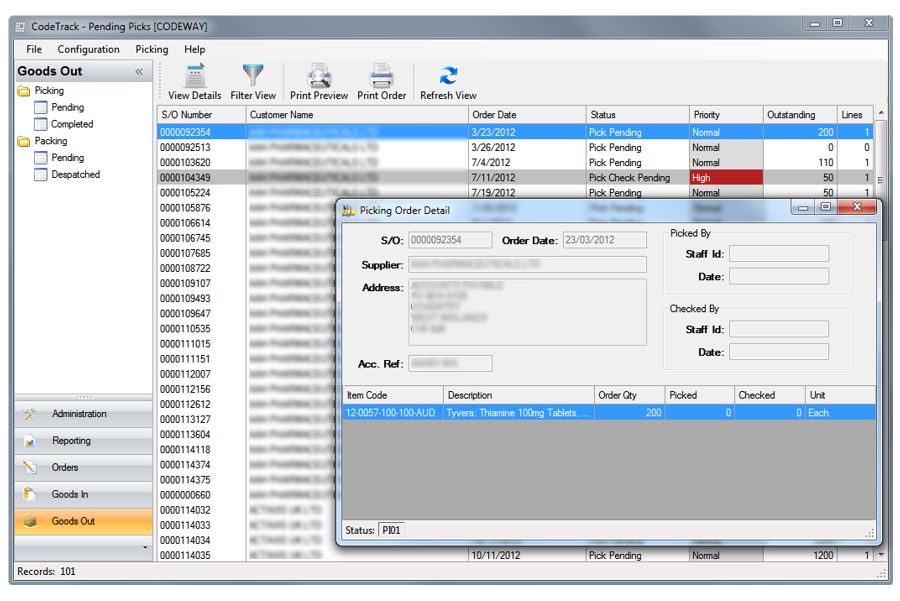

The sales order summary screen shows the status of each order.

The sales order summary screen shows the status of each order.

Supervisors use the sales order summary screen to define picking priorities.

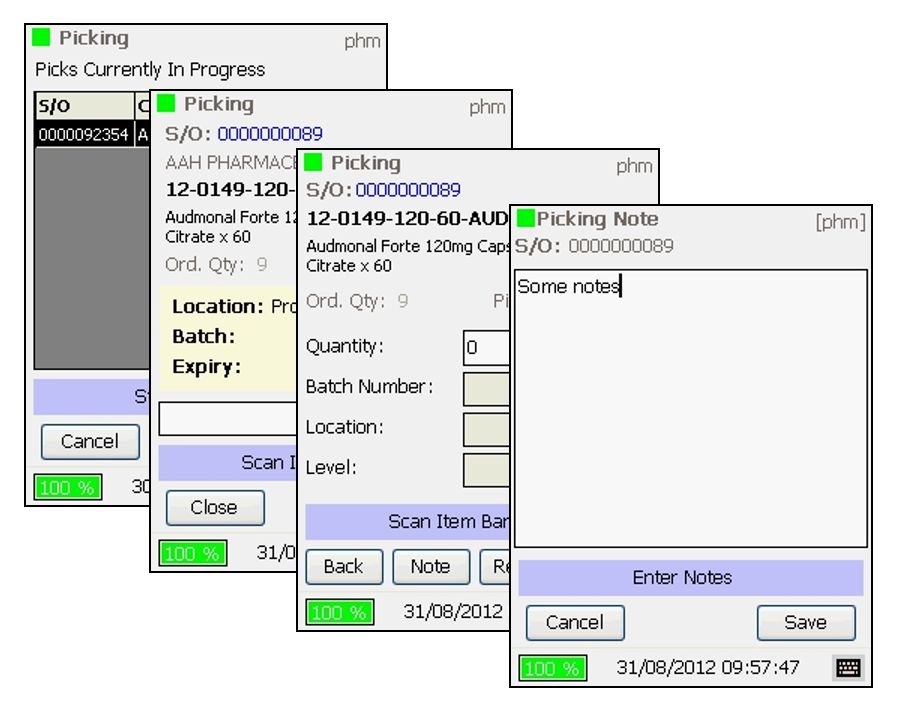

Picking screens.

Picking screens.

Codetrack allocates orders based on the next required picks and displays them with paused picks.

Simple screens guide pickers: select order · scan product · enter quantity and batch · note any problem.

Note: at the third step a picker may pick product from more than one batch to reach the total.

Pack

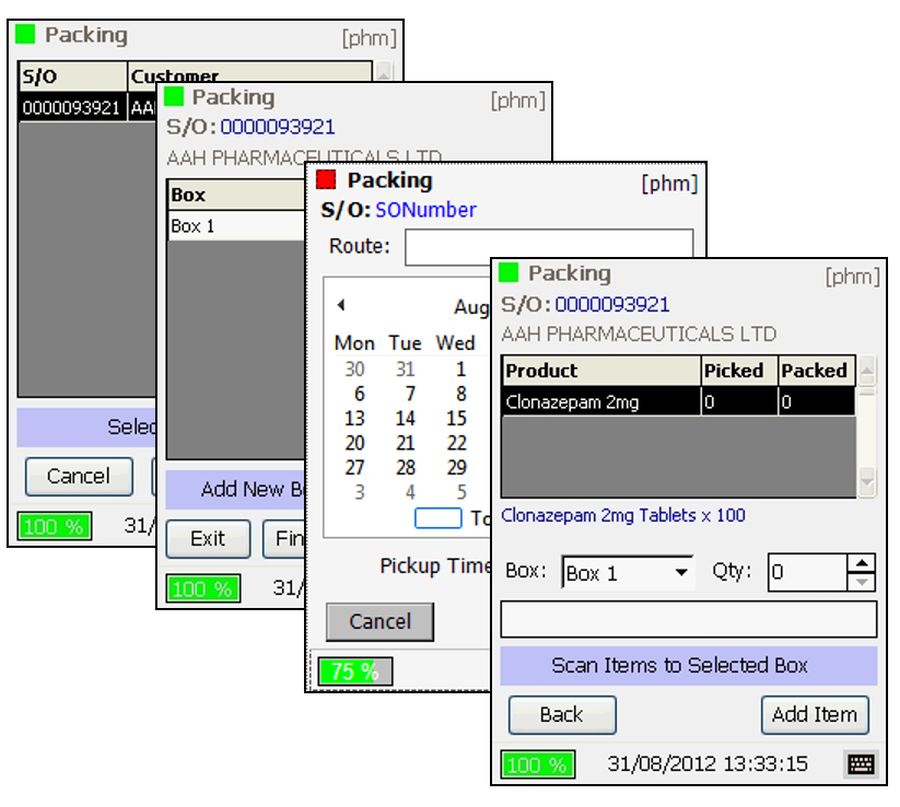

Packing screens.

Packing screens.

After the pick check Codetrack allocates an order to packing.

Simple screens guide packers: select an order · add new box, print box label · check routing middot; scan, pack, print packing slip, seal box.

Loop back to add a new box until the whole order is packed.

Warehouse management

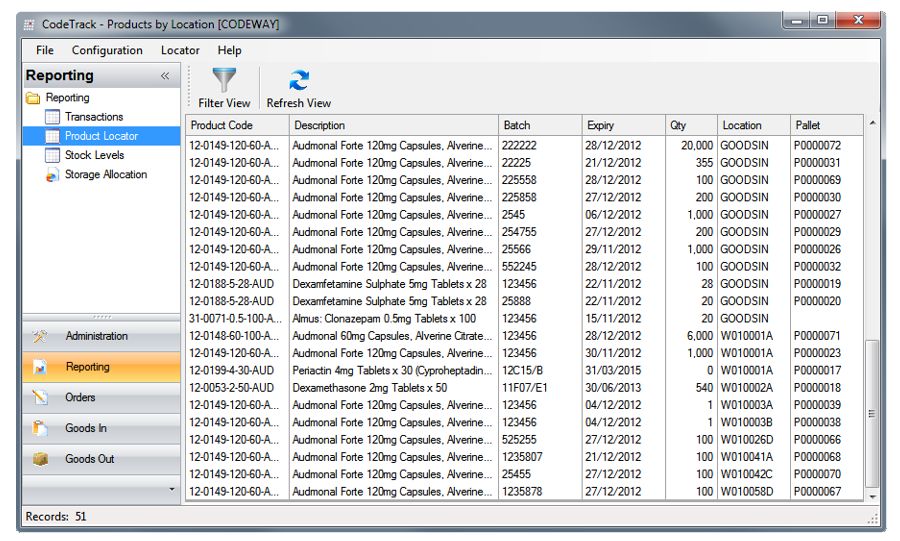

The product locator will find all locations of a product.

The product locator will find all locations of a product.

Codetrack provides several management functions:

- Product Locator: locations of a product.

- Stock Levels: stock by product.

- Storage Allocation: allocated and available locations.

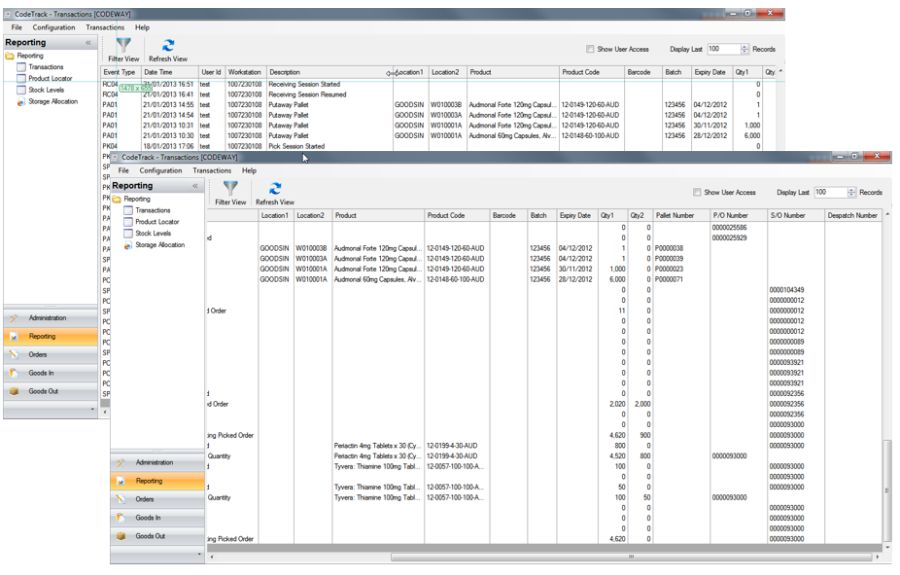

- WMS Transactions: log of all events.

- Filtered Views: drill down.

- Export: selected records to Excel or CSV.

Traceability

Codetrack logs the details of stock movements. Filters will find whatever you want to know.

Codetrack logs the details of stock movements. Filters will find whatever you want to know.

Codetrack has a Custom Filter Builder to set up traceability reports.

Examples:

- Batch traceability: all despatch records for a batch number.

- Problem resolution: all movement records by product, operator or container, within time limits.

Codetrack

This version of Codetrack uses Windows Mobile terminals. Current versions are available with Android terminals.

Codetrack works with Data Matrix 2D codes. A single scan can return product code, expiry date, batch code and a unique serial number. The result is an even more efficient, more reliable system.

Any Questions?

Related Applications