Simple Production Tracking System

The BellHawk Online Simple Production Tracking System (SPTS) monitors the status of orders and work-in-progress in real-time.

To add tracking of materials and finished goods, you can upgrade to the real-time operations system (RT-OPS). Optional modules such as BOM add the capabilies of a manufacturing execution system (MES).

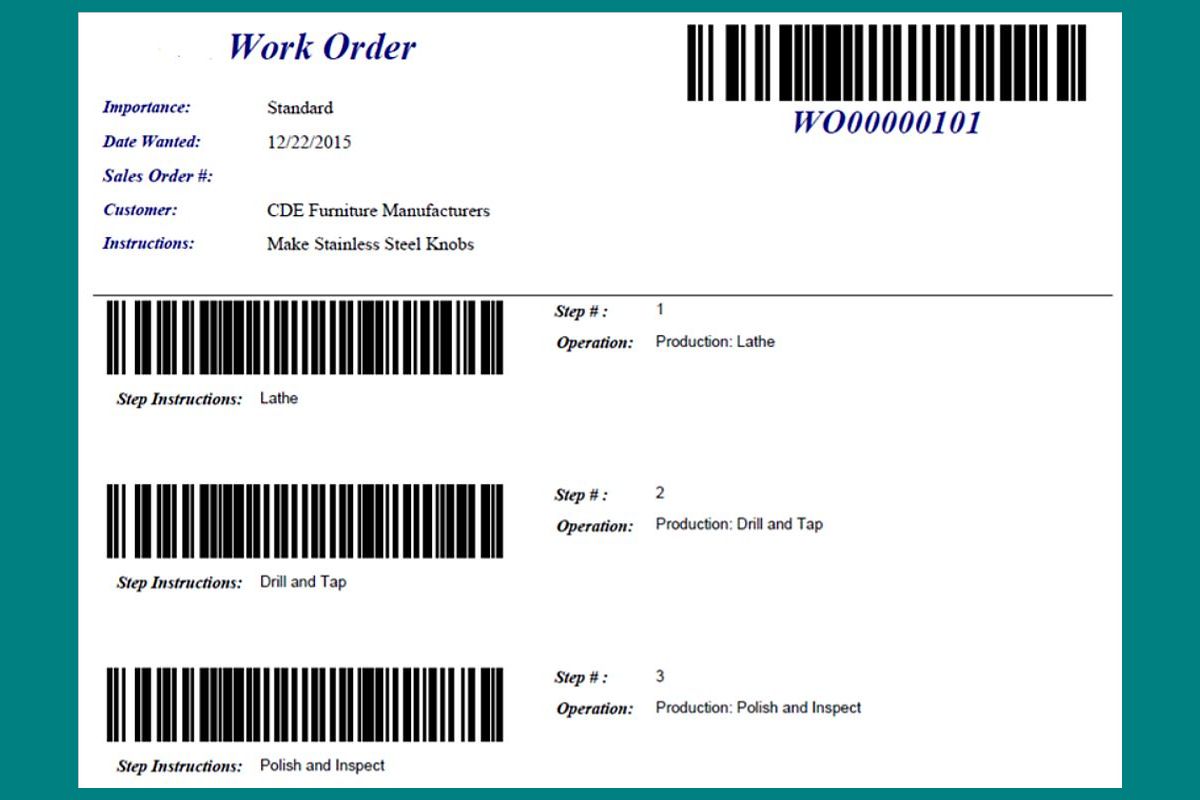

The system generates a barcoded ‘work order traveller’ to go along with a batch of parts or an individual item through its sequence of operations. Operators scan these barcodes to record the start and finish of each step. This is the simplest way to move to an electronic-real time system.

Applications by industry

- Manufacturing

- Fabrication

- Engineering

- Construction

- Assembly

- Repair

Results

Real-time visibility

The biggest advantage of SPTS is everyone can see the status of all jobs and resolve any problems on the spot.

On time shipment

The dynamic scheduling system makes the best decisions it can to ensure every work centre is geared to product shipment dates – just like a good operations manager. This relieves managers and supervisors of a huge work load to manage these schedules themselves.

Productivity · Performance

Real-time information and elimination of manual paperwork cuts errors, delays and costs.

How SPTS Works

Shop floor technology

BellHawk designed SPTS for people who may have no computer skills. Key data is captured by scanning barcodes and manual data entry is minimised. The system warns users as soon as it finds a mistake and helps them correct it.

Production routes

You can use SPTS to set up production routes or import them from another system. SPTS prints the barcoded work order travellers.

Work centre scheduling

When they complete a task, SPTS presents the operators in a work center with a prioritised queue of jobs. They should pick the top one unless they have a good reason to pick another. The prioritisation rules relate to when the final product is due for shipment, how long it may take to finish the remaining operations, the importance of the customer job, and other such factors. Scheduling is dynamic to take account of current status of all work centres and to allow for rush jobs.

Operation

Operators scan a barcode attached to their badge to log their start and finish times. They scan barcodes on the work order traveller to record the start and end of each operation. They can also record the quantity produced or processed.

Work time recording

SPTS will record the actual time to complete each operation, as distinct from the elapsed time. Users scan-out when they have a break or their shift ends. The system allocates time to jobs when an operator works on multiple work orders at the same time.

Work-in-progress status

Supervisors and customer support can see the status of all work orders in real-time. This includes how long each work order has taken and how long it has been waiting for the next operation to begin.

Management reports

Excel exports show the progress of work orders and how long they have been held up between operations. Other exports show the elapsed time, production time, and quantity produced for each operation by work order and by employee.

BellHawk Online Data Sheet

Simple Production Tracking System (SPTS)

BellHawk Online modules

Base systems

- Materials Tracking System (LP-MTS)

Track materials without the need to create or track orders. - Simple Production Tracking System (SPTS)

Track work order status and job times by operation. - Real-Time Operations (RT-OPS)

Track all aspects of production and materials.

LP-MTS and SPTS are entry level systems. RT-OPS adds many transactions for tracking operations and usage of materials.

The WMS bundle adds warehouse management to LP-MTS and RT-OPS

Manufacturing options

- Equipment Tracking Option (ETO)

- Work Centre Scheduling (WCS)

Warehouse options

- Warehouse management system (WMS) for LP-MTS or RT-OPS

- Purchase Order Receiving (PO, in WMS)

- Ship Order (SO, in WMS)

- Picking (PICK, in WMS)

- Shipping Dock Option (SDO, in WMS)

- Directed Zonal Picking (KIT) for assembly kits and ship orders

- Inventory Auditing Module (IAM)

Materials Traceability options

- Materials Traceability (TRACE) for RT-OPS

- Quality Control (QC) for RT-OPS

Operations Management options

- Project Tracking (PROJ) for RT-OPS

- Available Inventory Prediction (AIP) for RT-OPS

- Dynamic Demand Driven MRP (DRP) for RT-OPS

IIOT Interface Appliances

- Data Exchange Interface Box (DEX)

Provides for exchange of data between the plant and BellHawk Online. - Barcode Label Printing (BLPA)

Adds to all systems except SPTS. Needs a BarTender or NiceLabel Automation licence for the barcode label printers. - Weighing Scale Interface (WS)

Provides an interface for scales: floor, bench, lab. - RFID Interface (RFID)

Provides an interface for RFID data collection devices.