BellHawk Online helps you fulfil orders on time by scheduling and tracking materials and operations in real time.

Real-time Track & Trace

BellHawk launched barcode tracking systems for NASA and USAF suppliers in 1989. Today many North American firms use BellHawk systems to make and ship orders on time. Smaller companies have unlocked growth and divisions of larger enterprises have transformed performance.

On-time operations

The systems track all jobs and material movements in real-time. BellHawk Online uses this data and artificial intelligence to schedule manufacturing and warehouse operations, also in real-time. This will help you deploy your resources to meet ever-changing order delivery dates and priorities.

Smart data capture

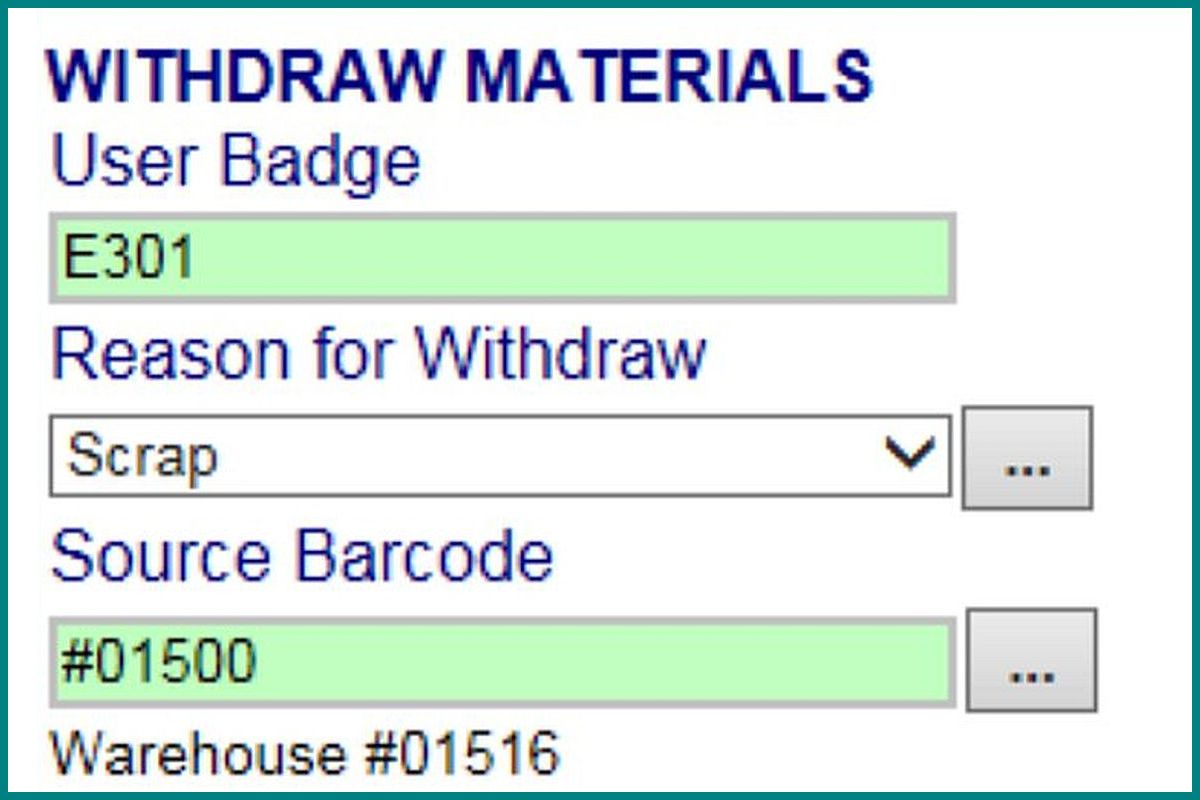

'Magic forms' help operators capture data on their terminals. The form adapts to the data as the user enters it. This minimises data entry—and avoids mistakes At the same time it ensures users record all necessary information, such as specific attributes for each type of material received.

Flexible configuration

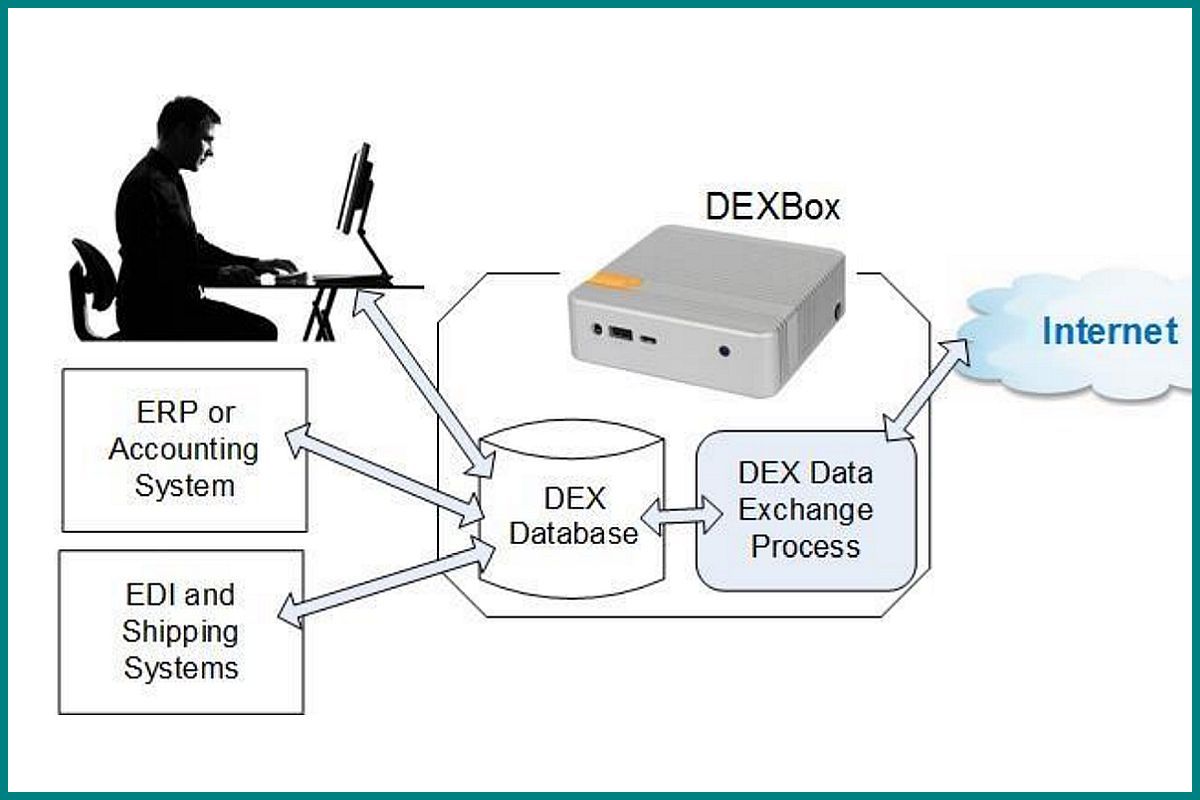

BellHawk Online is ready to use once we have configured the system for you. This involves importing spreadsheets with your master data together with parameters, constraints and business rules. We suggest you start simple then extend. BellHawk's DEXBox makes it easy to exchange data with your business systems.

Industries

Manufacturing • Conversion (rolls, sheets) • Packaging • Industrial Distribution • Construction • Engineering • Test & Repair • Food • Pharmaceuticals • Life sciences

Applications

Material tracking • Operations tracking • Product tracking • Asset tracking • Demand driven supply • Production • Warehouse • Quality Control • Traceability • Compliance GS1 GMP FDA • Automated Data Exchange • Real-time Business Intelligence

1. Key Features

All BellHawk Online systems feature real-time tracking and traceability, smart data entry, multiple units of meaure and product variants. Automatic data exchange with your business systems is built in. As is support for printing labels on demand, complying with standards like GMP and FDA, and advanced options.Materials · Operations

Realtime Tracking

How to control materials and operations at your facilities and project sites with tracking numbers.

Data Entry

Magic Forms

How magic forms stop mistakes and capture the right data every time. Nothing could be simpler!

Size · Colour · Options

Product Variants

How to track to attributes like colour, length, grade and options with no extra part numbers.

Integrated Printing

Labels · Documents

How to print labels on demand and generate ASNs for parts, products and nested packaging.

Data Exchange

Systems Integration

How to exchange real-time data with business systems for orders, operations and inventory.

Quality · Traceability · GMP/FDA

Compliance

How to control quality and traceability. Comply with GMP/FDA rules. Avoid risk and chaos!

2. BellHawk Online Base Systems

MATERIALS TRACKING and SIMPLE PRODUCTION TRACKING are starter systems. They may be all you need.REALTIME OPERATIONS adds many more functions. It is the basis for full manufacturing, warehousing, installation and traceability systems.

WMS WAREHOUS MANAGEMENT options work with MATERIALS TRACKING or REALTIME OPERATIONS.

3. Warehouse Options

The BellHawk Online WMS option adds a warehouse management system to a MATERIALS TRACKING or REALTIME OPERATIONS base system.The WMS bundle consists of four modules: PURCHASE ORDER, SHIP ORDER, PICK and SHIPPING DOCK. Each is available separately. DIRECTED PICKING and INVENTORY AUDIT are the two extra warehousing options.

Warehouse WMS Option

Shipping Dock

Warehouse Extra Option

Directed Zone Picking

Warehouse Extra Option

Inventory Auditing

4. Production Options

How it worksManufacturing option

Equipment

• Track operation times and machine status

• Record plant and equipment utilisation

• Allocate costs to work orders and products

Manufacturing option

Scheduling

• Schedules operations in real-time

• Adapts to events and rush orders

• Supervisors can view status and adjust priorities

Materials Traceability Option

Quality Control

• Monitors all materials in need of inspection

• Records all checks and proves compliance

• Prevents use or shipment of defective material

Materials Traceability option

Traceability

• Maintain lot and serial number traceability

• Trace back to source and forward to customers

• Comply with GMP/FDA and other regulations

5. Operations Management Options

How it worksOps Management option

Project

Ops Management option

Inventory Prediction

• Do the complex calculations.

• Predict materials by date.

• Decide what to make or buy.

Ops Management option

Demand Driven MRP

6. Industry Systems

How it worksIndustry System

Convertor

• Convert units of measure for rolls and sheets.

• Track multiple jobs on the same machine at once.

• Account for reusable materials, rework and scrap.

Industry System

Construction

• Track materials, fabrication and installation.

• Cover multiple facilities, vehicles and sites.

• Allocate costs and materials to projects.

Industry System

Pharmaceutical Traceability

• Control ingredients • Serialise products.

• Trace materials, mixes, products, packaging.

• Comply with GMP/FDA process standards,

7. Operations Management Systems

How it worksOperations System

Manufacturing

• Track operations in realtime

• Schedule work centre jobs

• Simplify material planning

Operations System

Warehouse

• Receive • Pick • Pack • Ship

• Monitor orders in realtime

• View inventory in realtime

Operations System

Materials Traceability

8. IIOT Interface Applicances

How it worksIIOT Interface Appliance

Data Exchange Box

• Exchange data with ERP and accounting systems

• Read and write data from local tables

• Exchange ASNs and other supply chain data

IIOT Interface Appliance

LABELBox

• Automate label printing across the plant.

• Print on demand during data capture.

• Eliminate labelling delays and errors

IIOT Interface Appliance

Weigh Scale Interface

• Include weight in transactions automatically

• Convert weight to count, length or area

• Print barcode labels with weight and other data

IIOT Interface Appliance

RFID Interface

• Automate tracking at key points

• Record new location of item or container

• Ideal for tagged pallets and totes