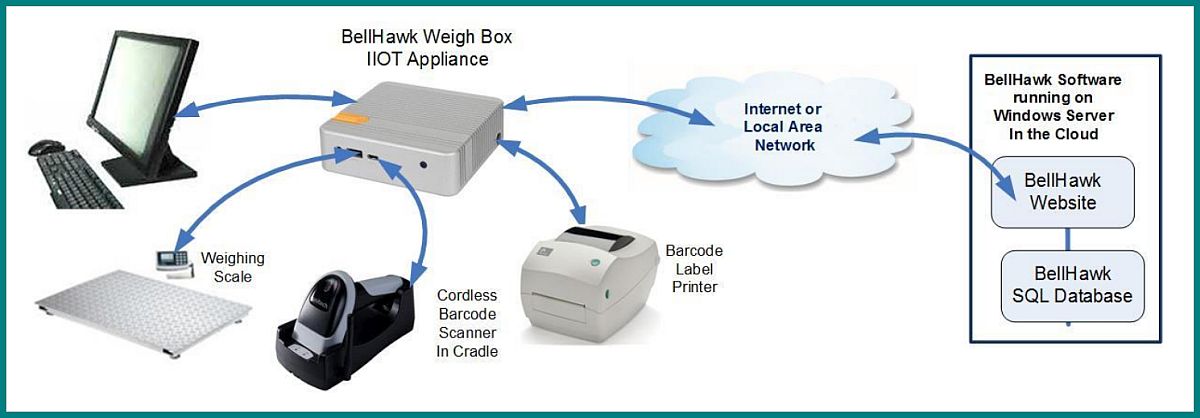

A WEIGHBOX sends the weight of material in a container to BellHawk Online. It can generate labels on a barcode printer

Weigh Scale Interface

The WEIGHBox provides an automated data collection interface to weighing scales. It takes stable weights and automatically relays them to BellHawk Online for inclusion in transactions. This saves time and eliminates errors due to manual entry of weight.

Typically one or more weighing scales are connected to a WEIGHBox. For example, a floor weighing scale and a bench scale used according to the type of material and container.

Weighing

When handling materials operators place a barcoded container on a scale. They scan its barcode and the WEIGHBox sends its weight to BellHawk Online for inclusion in the transaction. The tare weight was recorded when registering the container or type of container.

Process

• Monitor Software running in the weigh box periodically reads each weighing scale by sending an interrogation string to its controller.

• Detect If the weight has changed significantly from the last reading, this program makes a number of readings until it detects a new stable weight.

• Record It then sends this new stable weight to the web-services interface of the BellHawk software, where this weight is stored in the BellHawk database.

Quantity

Some BellHawk transactions need to calculate the quantity of material (count, length, area) from its weight.

• Scale Select the scale by scanning its barcode.

• Display Device shows the measured gross weight and the tare weight of the container.

• Compute Device also shows net weight (gross weight - tare weight).

• Convert If weight is the secondary UOM the net weight is converted into a quantity: count, length, or area depending on the conversion factor for the material.

• Record BellHawk stores the net weight or quantity according to the primary UOM

Data Collection

WEIGHBox Terminal mode

A WEIGHBox can be used as a BellHawk online data collection terminal, with a monitor, mouse and keyboard.

Label Printing

In terminal mode the WEIGHBox can drive a label printer through its USB port. The enables it to print a barcode label with the weight of material in the container together count, length or area.

Installation.

Scale parameters

Weigh scale parameters (such as name, interrogation period and delta value for new stable weight) are setup from a spreadsheet, using the standard BellHawk Excel import mechanism.

Connection

The WEIGHBox provides RS232,USB and Bluetooth interfaces. An Excel import table can set it up when the scale responds to a simple interrogation string with a number, representing the weight in some pre-determined unit of measure. Connections to other scales wih more complex interaction protocols can require some customisation.

BellHawk Online Data Sheet

Weigh scale transaction interface appliance (WEIGHBox)