Printing labels on demand as part of data entry avoids labelling mistakes, ensures database accuracy, and saves time.

Automated Label Printing

Pre-printed number plate labels track materials in containers but how to print labels for products, packages and shipments?

Magic Forms let you print labels on demand during the transaction. This eliminates error and saves a lot of time.

Real-time labelling

The powerful BellHawk TAG module will automate on-demand label printing throughout your operation. It prints labels for your users to apply as they complete each transaction such as receiving a bundle of material or packing a product.

Major benefits

Automated label printing brings major benefits. It will eliminate most potential labelling errors and the disruption they cause. Your operators and materials handlers will also save a huge amount of time.

Labelling issues

Compliance

Customers expect all product packaging and shipping containers have the correct labels.

Unique identification

Many items must have a unique label with a serial number, lot number and expiration date.

Customer requirements

Some customers specify how suppliers must label their consignments.

Advance Shipping Notices

Some customers require ASNs to include key data from the barcode labels in the delivery.

Manual labelling

Typing data into a label printing program is time consuming and error prone. It is often incompatible with capturing data for ASNs.

Penalties

Every failure risks rejection of a shipment and financial penalties.

The Solution

User request

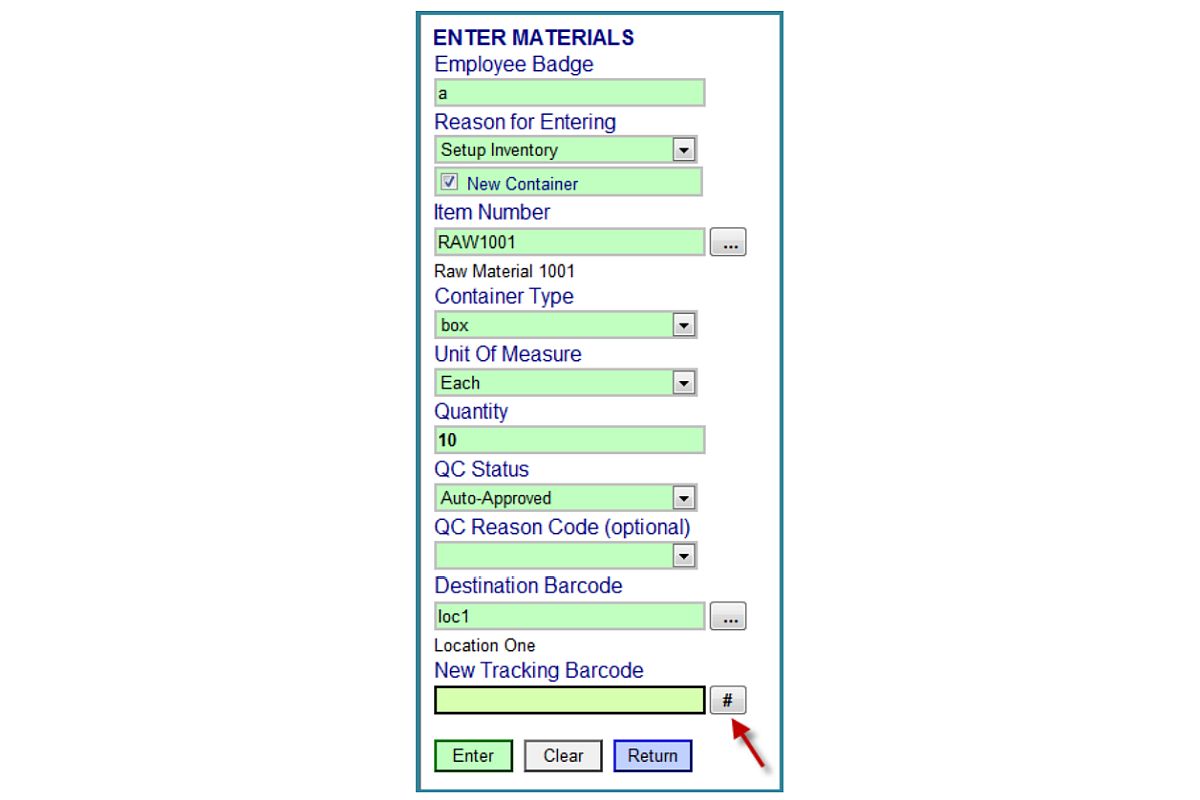

BellHawk adds a print button to data entry screens when barcode label printing is installed.

TAG rules

When BellHawk receives a label print request it follows the TAG rules for your system. A good time to enter these rules is when you create a label format in Bartender or NiceLabel.

TAG rules are based on factors such as:

- Customer

- Part number

- Product category.

- Material type.

- User defined parameters such as grade, hazardous materials rating.

- Status such as QC pass/fail, expiry date.

- Type of container such as box, bottle, pallet.

BellHawk use these rules select the label template, select the printer, retrieve data to print on the label and generate serial numbers. It places this data in a print queue.

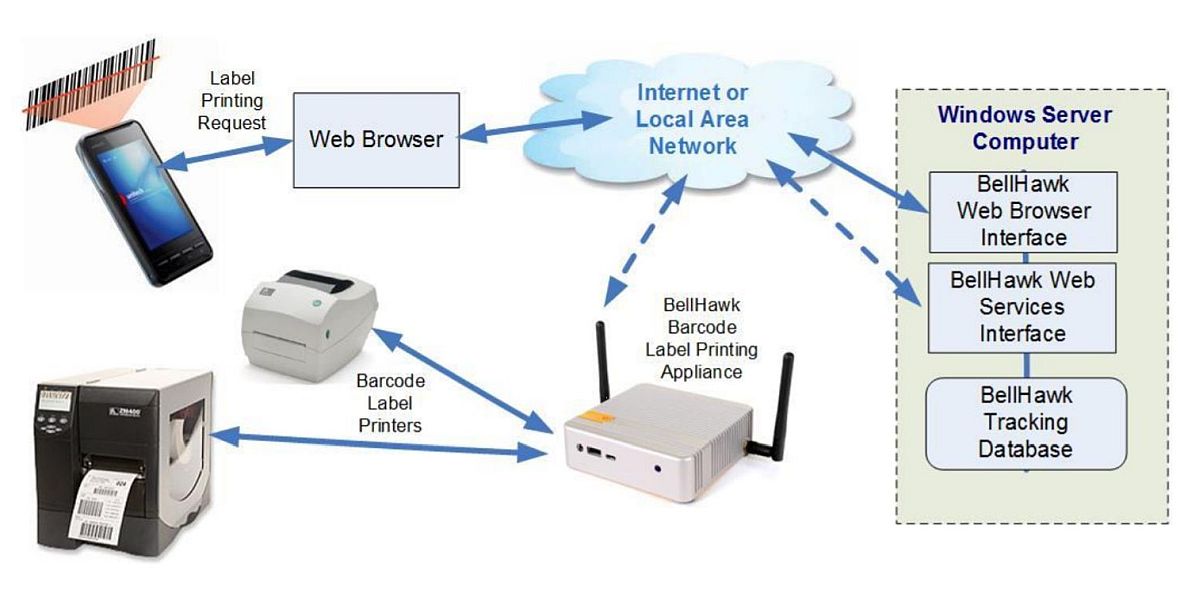

Label printing

The Barcode Label Printing Appliance (BLPA) at your site continuously monitors the print queue on the BellHawk server. When BellHawk puts a label in the queue the BLPA calls up the label format, populates it with the data from the server, and prints the label on the selected printer.

The Barcode Label Printing Appliance (BLPA) at your site continuously monitors the print queue on the BellHawk server. When BellHawk puts a label in the queue the BLPA calls up the label format, populates it with the data from the server, and prints the label on the selected printer.

The BLPA runs Bartender Automation or NiceLabel automation to print labels. This means you can use Bartender or NiceLabel to design templates for a wide range of desktop and mobile label printers.

TAG Advantages

- Automated printing with TAG rules prevents labelling mistakes.

- Avoids chaos at the customer site when labels are wrong or do not correspond to ASN data.

- Requires no training for users on how to operate a label printing system.

- Saves the seconds or minutes users would to enter data and print each label manually.

Download PDF

BellHawk Online Technical Note

Label printing system

BellHawk Online Technical Note

Preventing labelling errors

BellHawk Data Sheet

Labelling rules