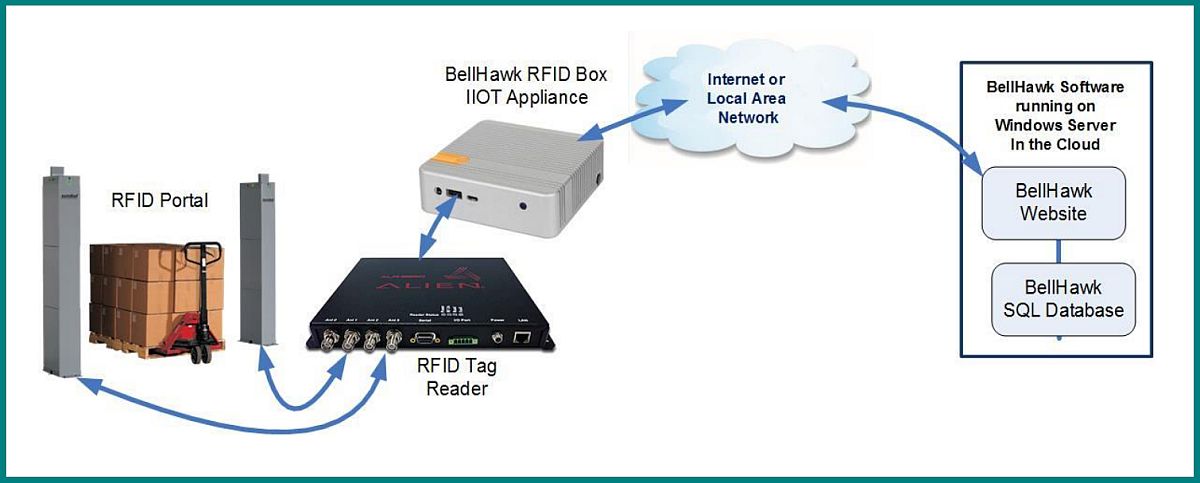

An RFIDbox will support many readers and portals across a facility. It extracts data to update the location of items and containers.

RFID Interface

This BellHawk IIOT box provides an automated interface for many RFID data collection devices.

The box lets you track tagged items and containers as they pass readers and portals at your facility. Each time it extracts the tag ID and the reader location. BellHawk Online uses this information to update the location of the tagged item or container.

The big advantage of items and containers with RFID tags as well as barcodes is process flexibility. You can choose to scan the barcode or the RFID tag at each tracking point.

Applications

RFID is advantageous for applications such as: • Loading and offloading of pallets at dock doors. • Tracking totes of WIP materials. • Validating critical items like samples in a laboratory.

Tag readers

The RFID box will work with most tag readers. It is likely BellHawk will have to add some custom code to handle differences in communications protocols.

Tagging

BellHawk stores the barcode number and the RFID code for tagged items and containers. These may already be tagged (e.g. returnable containers) or you may have to tag them yourself (e.g. stretch wrapped pallet).

The basic process is to identify and register the item them move it to a location for storage or processing.

Once BellHawk has registered the barcode and the tag, a material handler can scan the barcode to record its new location.

Tagged Items · Containers

RFID Coded Label (printed on demand) Generated by a label printer with an RFID reader to decode the tag. Apply the label then scan the barcode to register the tag.

Coded Label (pre-numbered) Apply a pre-coded label, then scan the label and the tag with a device that can read both together or one after the other.

Untagged Items · Containers

RFID Label: printed on demand Generated with a RFID label printer that reads the tag in the label and prints the tag code in a barcode. Apply the label then scan the barcode to register the tag.

Ruggedised Tag: prenumbered An outsourced RFID tag with a barcode label encoding the tag number. Attach the tag to the item then scan the barcode to register the tag.

Tracking

Automatic (tagged items)

BellHawk will track the movements of items and containers when there are tag readers connected to the RFID box at key locations around the plant.

The system will update the location of an item when it receives a message from the RFID box. Each message contains the tag code together with the ID of the portal or antenna which detected it.

Manual

Operators can perform other operations on all items and containers by scanning their barcodes.

Examples • Putting a tagged or untagged item on a shelf • Removing a quantity of material from a tagged or untagged container.

RFID · Barcode

Single tags (tote, pallet)

When recording the movement of a single item, RFID can be highly accurate. The item might be a tote bin on a conveyor or a pallet at a dock door.

Multiple tags (items in box, packs on pallet)

Portals can read mutiple tags. These might be items in a box or packs on a pallet (cartons, crates, sacks). Testing is essential but liquids and metals are not good.

As a rough average, portals will read about 98% of tag on pallets moving at walking pace with half a dozen packs. This may fall below 90% at higher speeds for pallets with more packs.

Barcodes (item, container)

For most applications barcode scanning is far more flexible.

BellHawk Online Data Sheet

RFID tagged material tracking appliance (RFIDBox)

BellHawk Online Data Sheet

IIOT Box datasheet