Directed Zone Picking (KIT)

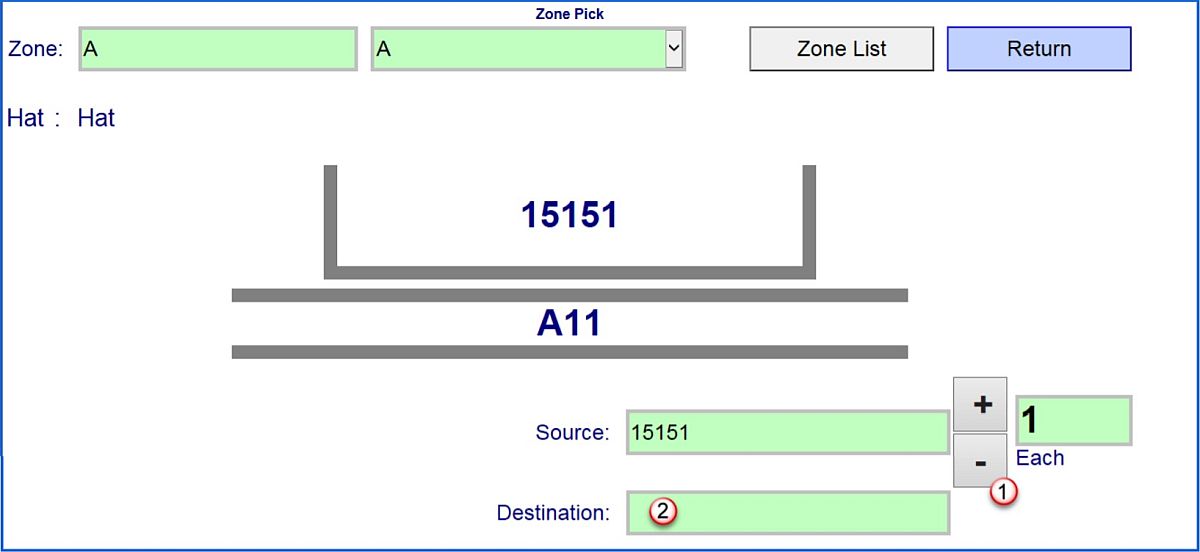

Pick one item from bin 15151 at A11 (zone A, location 11). Picker: scan barcode on bin (Source), confirm/reduce quantity (1), scan barcode on box (Destination)(2) to submit. System: check Source and Destination have the right parts. Smarts: to customise process.

Directed Zone Picking guides pickers to assemble kits for production operations and to ship orders to customers. Companies tend to pick in different ways. BellHawk and Codeway will add "smarts" to customise the process for special requirements.

Applications

Directed picking is optimal for picking parts from many locations and bins. Pick sheets are efficient for a small number of parts from widely separated locations.

Capabilities

Warehouse Organisation

Locations Clusters of locations are assigned to zones.

Sequence Zones are sorted alphabetically, locations numeric. Custom sequences can be implemented with "smarts".

No Map The algorithm produces an efficient picking sequence with no need for a map of ad-hoc floor locations.

Pick Orders

Orders KIT processes the same orders as PICK.

Production Pick orders exclude materials held as production stock: line-side, silos, etc.

Algorithm System retrieves location of all stock for each order then generates an efficient pick route.

Bill of Materials Algorithm can use nested BOMs for kits of parts; typical examples: circuit boards, medical kits.

Route Takes into account availability of parts in different locations and their proximity to each other.

Picking

Source Device displays location, bin (if used for item), quantity. Picker scans bin or location barcode.

Destination To confirm transfer picker scans barcode on destination container: basket/box/pallet/etc.

Shortages When bin/location has insufficient stock, picker records actual quantity picked, system zeroes bin/location quantity.

Check System confirms Source contains correct parts and Destination contains only parts for the selected Pick Order.

Errors Device displays error. Picker restores item and repeats the item pick.

Self-direction Material handlers may select another zone to avoid busy aisles and delays.

Dynamic updates System regenerates the pick on completion of each zone to allow for changes in orders and inventory.

Management

Visibility Material managers can see the quantity of parts picked against the original pick order.

Changes Late changes can be made in real time.

Missing items Regenerates the pick for incomplete orders when stock available.

Smarts*

Business rules AI rules imported at setup minimise the need for custom code blocks ("smarts")

Warehouse sequence Enables warehouse manager to vary or replace strict alphanumeric order.

Attribute sequence Enables materials manager to specify picks according to attribute, such as heaviest first.

Multiple orders Pick several orders at once into different destination container.

Aggregated orders Combine orders for picking, such as bulk of single items.

Partial orders Split orders for picking and consolidation, such as by warehouse or stock room.

Custom rules Implement other special requirements, such as picking alternative pack quantities.

* — also consider a Codetrack WMS to meet special requirements.

BellHawk Online Data Sheet

Directed Zone Picking: Assembly Kits, Ship Orders (Kit)

Requirements

Base system

Material Tracking (LP-MTS) or Real-time Operations (RT-OPS)

Modules

Warehouse Picking (PICK) or WMS bundle (PO · SO · PICK · SDO)