BellHawk Online Operations Management System

Materials Tracking • Traceability

Track · Trace

Track what comes in, what goes out, and what happens in between.

The BellHawk Materials Tracking Traceablity System (MTTS) is a barcode system suitable for many tracking and traceability applications in industry.

MTTS has full capability but costs much less to implement than systems designed for large organisations.

Purpose

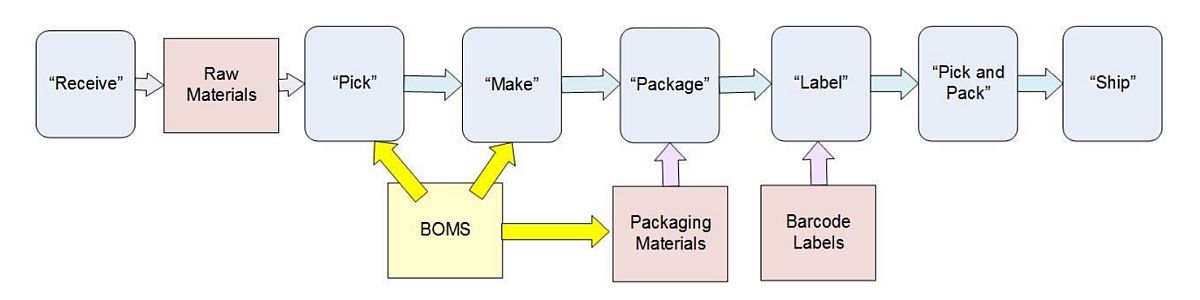

• Track the transformation of raw materials into finished products

• Build a database to trace the links between finished products and their materials.

• Save lots of time by replacing forms and keyboards thereby avoiding many mistakes.

Applications

• Automotive parts • Aerospace components and subsystems • Building materials and components

• Engineering components and assemblies • Medical devices and supplies

• Test and repair of safety critical systems, assets and instruments.

Capabilities

1. Materials

Purchase Receive against PO, record supplier lot number, expiry date, special user defined attributes (requires WMS).

Storage Identify containers with barcoded numbers linked to materials record.

Quality Track status: awaiting inspection, pass/fail ...

2. Production

Units of Measure Work in multiple units and convert between them, such as weight to length.

BOM Store and use bills of materials and formulas.

Mixing Prevent mistakes like using materials due for inspection or past their expiry date.

Operations Track who worked on each operation and what equipment was used.

Quality Control Monitor tests, approve materials for use, check equipment, and keep records.

Materials Track materials, work-in-progress, intermediates, finished products, and packaging materials.

Packaging Check materials are correct, and lines are ready for use.

Labelling Print and apply item, box and pallet labels with the same data as ASNs (requires LABELBox).

Serialisation Print and apply serialised barcode labels to items, containers and nested containers.

3. Fulfilment

Picking Select products against SO (Ship Order), check the right products are picked and transferred to correct pallet or container (requires WMS).

Nested containers Track nested containers and their contents.

Shipping Check the correct containers are loaded.

ASNs Capture 100% accurate ASN data.

4. Data Exchange

Interface Automate data exchange with your business systems (requries DEXbox)..

Purchase orders Import purchase orders (POs) to track receipt, storage and quality status materials.

Sales orders Import ship orders (SOs) to generate work orders (WOs) for make to order products and pick orders for shipping finished products.

EDI Relay ASNs to customers via third-party Cloud EDI systems including nested cointainers (requires DEXBox).

5. Traceability

Tracking Capture all the data you need for traceability.

Compliance Follow standards and regulations:

• Trace through records of materials, operations and QC

• One step back to suppliers

• One step forward to customers.

Mock recall At the touch of a button as large customers expect.

Recall Be ready for a rapid recall.

Realtime Tracking Advantages

Visibility

BellHawk MTTS Online provides managers, supervisors and customer service with a realtime view of the status of business operations:

- Inventory

- Production

- Orders

Data

Material handlers and line operators scan barcodes instead of filling forms or keying in data. This avoids lots of errors and saves many people a lot of time.

Alerts

BellHawk checks every item of data at the point of entry and alerts the operator when it detects an error.

These point-of-action warnings are to avoid expensive mistakes such as:

- Picking the wrong material

- Using a batch of material after its expiry date

- Using materials that failed inspection.

Recall ready

Always be ready for a rapid recall.

BellHawk Online Data Sheet

Materials tracking and traceability system (MTTS)

Base System

Real-Time Operations Tracking System (RT-OPS)

Modules

Materials traceability module (TRACE) Quality Control (QC) module.