Coffee makers are one category in the 10,000 SKUs in the company's kitchenware and appliance catalogue

A cookware retailer had grown from one shop to more than 20 outlets. Their point of sale system managed inventory at its distribution warehouse. Goods receiving was still a paper process.

The company was in a quandary. Goods receiving was slow and prone to error. Their business system was unable to do the job.

Their new warehouse manager called in Codeway to resolve the problem. Codeway had supplied a warehouse system to his previous company, a cookware brand.

Problems

The warehouse manager explained:

- Purchase orders and goods-in notes covered most deliveries but not all.

- Products came in with different types of barcode.

- Supplier barcodes in the point of sale database were inaccurate.

- Goods in staff had to print and apply store labels to every item.

- The point of sale system allocated orders to stores.

- The warehousse adjusted allocations to match actual quantities.

- Breakages were significant..

Solution

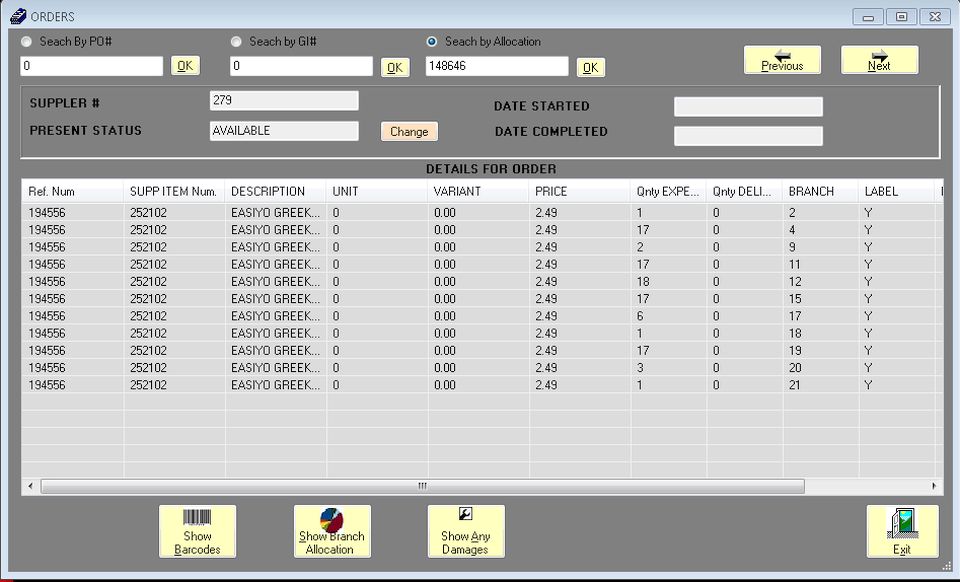

Codetrack imports purchase orders and store allocations from the point of sale system.

Codeway set up a Codetrack system to run goods-in. It imports purchase orders and planned store allocations. After goods-in receives the goods Codetrach returms the actual allocations.

Codetrack maintains master product data. The table holds accurate supplier codes and store label data. It enables goods-in to process deliveries without delay.

At installation the warehouse had 5 goods-in workstations, now there are 14. Each workstation has a store label printer.and a handheld computer. These have network and WiFi links to the Codetrack database.

Arrivals board

Codetrack displays an up to the minute table of arrivals and their status:

• Expected

• Labelling (in progress)

• Labelled and Received

Register order

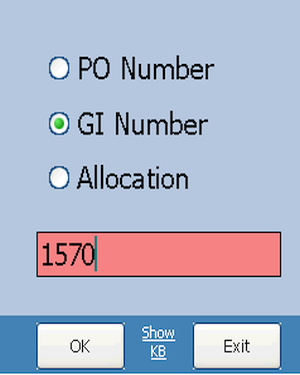

When goods arrive at a workstation the operator registers the order on the handheld terminal.

The operator selects the type of order and enters the order number.

Scan and count

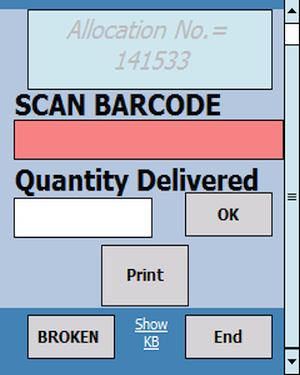

• After entering the count operators click the print button to print and apply the labels.

• They continue until they have counted all the products in the delivery.

• The screen cycles until all products are counted.

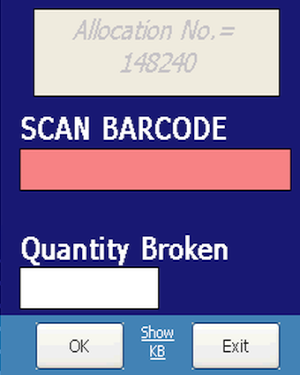

• They press the BROKEN button when items are damaged.

• The END button confirms the delivery.

• Codetrack adjusts store allocations to the quantities received. It exports the results to the point of sale system.

Shortages

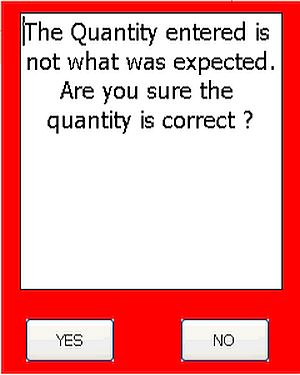

• Codetrack asks the operator to confirm partial quantities received.

• Operator confirms partial count or goes back a step.

• When deliveries are jumbled up. Operators may have to scan and count the same product again.

Record breakages

• Operators scan and count breakages.

• Operators can count breakages for one product or all products at once.

Screens

Codeway proposed handhelds designed for intensive use but the budget only ran to small screen units. Some operators found them difficult to use so, to help them, Codeway increased the size of fonts and buttons. Today, Android terminals resolve such issues.

Results

• 180% increase in volume over 7 years.

• Breakages down to low levels.

• Supplies administration simplified.

• Data entry costs eliminated.

• Stores allocation automated.

• Payback within months.

Related Applications

Retail Distribution

Global traceability

Retail Distribution

Home Appliances

Retail Distribution

Homeware

Enterprise Mobility

IBM Emulation