Compound conditioning is key to polymeric product quality. They must be in equilibrium and not expire before use.

Waste up · Quality down · Problem solved

A supplier of moulded car components was struggling to meet its schedules for Jaguar Land Rover schedules. The problem was the moulding compounds were not always ready for the next job. This led to excessive overtime, quality below target, and increased waste.

More than sufficient raw material was in stock. Not enough was available when needed because much of it was in conditioning and quarantine. The inevitable result of overstocks was some compounds went beyond their expiry date and had to be scrapped.

A telltale sign was the sight of storemen writing out goods-in details on paper.

Today

Deliveries are on time, waste is minimal, quality is high.

New process

- Suppliers label crates with barcodes.

- Storemen scan all movements for 100% stock accuracy.

- Issues are FIFO.

- Little or no stock expires.

- The Codetrack system updates material requirements daily.

- Staff and suppliers manage materials on a web portal.

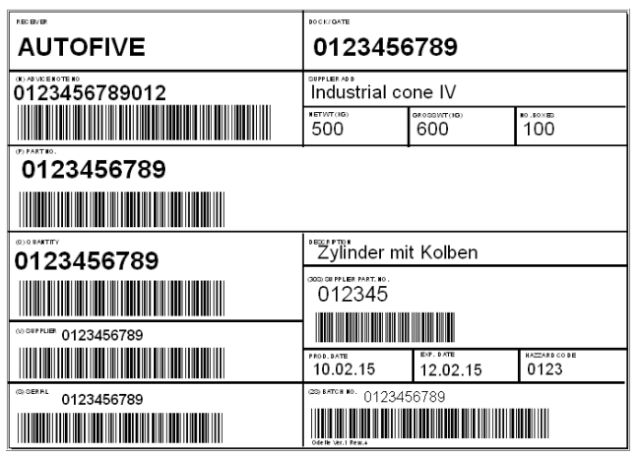

Odette labels identify batches of material (image: NiceLabel).

The Project

Codeway had already supplied the company with a system to verify despatches. Discussions with the project team and suppliers now led to three goals for materials:

- Accurate stocks,

- FIFO issue to production,

- Rolling schedules for suppliers.

Stocks

Storemen used to write down delivery details. Now suppliers put an Odette label on each crate.

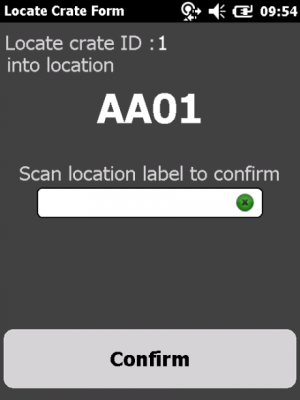

Storemen have wireless terminals to scan the crates and direct them to storage locations. QA scan crates in and out of quarantine.

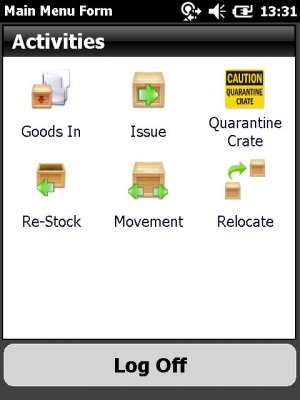

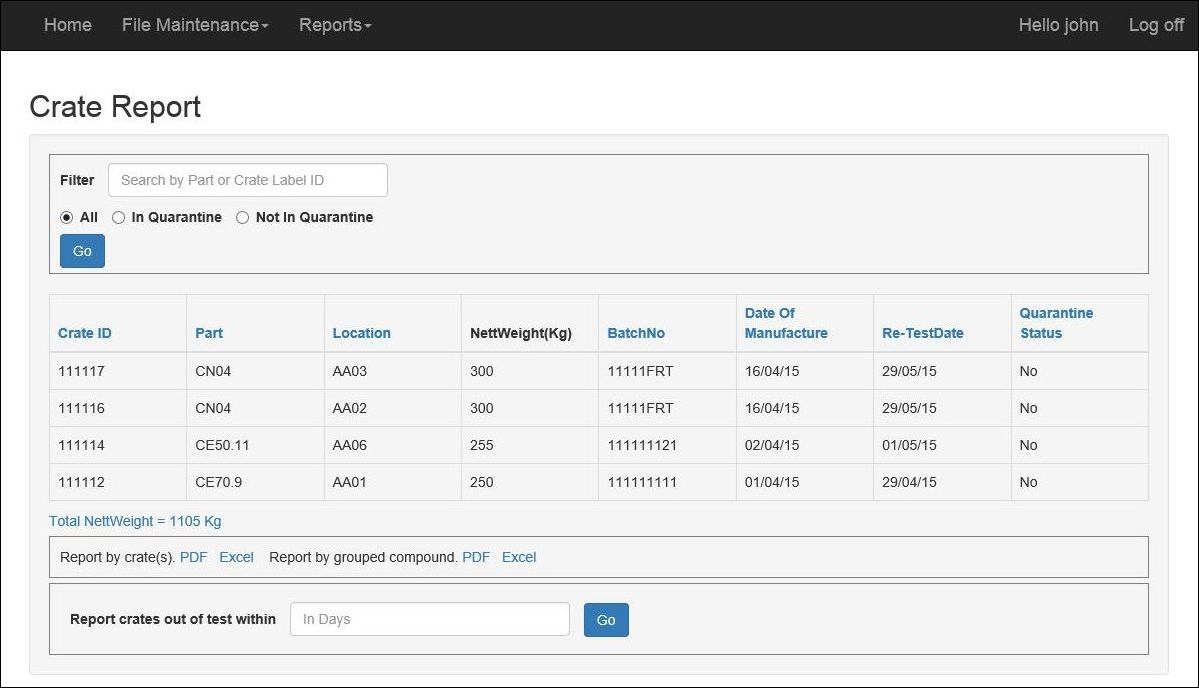

Codetrack stock management menu

FIFO

Production teams request materials on demand. Lists of crates and locations in FIFO order come up on the storemens' terminals. They scan the crates and issue them.

It is impossible to issue crates in conditioning and quarantine.

After production the storemen weigh and relabel part used crates. They scan them back into stock.

Storemen confirm locate each crate.

Rolling supply schedules

Today staff and suppliers have a Codetrack web portal to manage supplies. It links to the company’s ERP system.

This report shows how the unique crate ID controls materials by type, location, weight, date and status.

Codetrack works out future demand for materials every day from JLR component schedules and stocks. It does the calculations to allow for current ordewrs, stocks and conditioning times. The manufacturer's team and suppliers use this 'hymn sheet' on the portal to schedule supplies and production.

Related Applications

BellHawk Manufacturing

Automotive Parts

Automotive · Sequencing

Car body parts

Automotive parts

Despatch Verification

Automotive parts

Fuel systems

Automotive components

Interior assemblies

Automotive Parts

Machinery Spares

Automotive assembly

Performance Vehicles

Material Supply

Polymeric materials