Inspectors use rugged handheld computers to inspect vehicles following the protocol the customer specifies in their contract

Business transformation

This company provides logistics quality audits to automotive manufacturers, insurers and logistics service providers. They carry out 1.5 million inspections every year on vehicles in compounds and at ports.

After talking to three track and trace systems specialist the company decided to work with Codeway. The Operations Director observed, “Codeway has deep knowledge of deploying electronic data capture and tracking systems with specialist insight into the automotive arena. With Codeway on board, we moved on to spec the project with particular attention focused on device and application requirements."

Requirements

Contract configuration

A web portal for customers and the company to agree detailed inspection protocols for their contracts. This included capability to set up new data collection variable quickly and easily without programming.

Inspection

Rugged handheld computers to scan vehicle identification barcodes and enter inspection results using "splats" displayed on the screen. Inspection sequences and data collected were to follow the contract protocol. The handhelds were to send the results to the web server and print mini-reports to attach to vehicles.

Reporting

A web portal for the company and its customers to display and download inspection results. Reporting criteria were to be user configurable.

Business value

There were huge potential benefits for the company and its customers.

Company productivity

- Elimination of time, costs and errors associated with rekeying data from paper forms into the back-office system;

- Up to date, accurate information and records;

- Real-time reports for managers to see and deal with problems before they affected customers;

- Creation of new forms for additional makes and models;

- Configuration of new services within the system.

Customer service

Logistics companies would have immediate access to inspection reports on new carts at ports, vehicle pounds and railway hubs..

The Operations Director gave a frank description of the problems they faced, “Information from inspections took a long time to reach customers who were often contacted with complaints about damage to a vehicle before they were aware this had happened. They then had to back track to trace the vehicle and cause of damage to effectively manage claims. This could easily become a full-time job so speeding up the flow of inspection information would add great value to our customers.”

The Codetrack application

Analysis

The team analysed how inspectors work and each manufacturer's criteria for checking their vehicles. This information defined the core capabilities of the system.

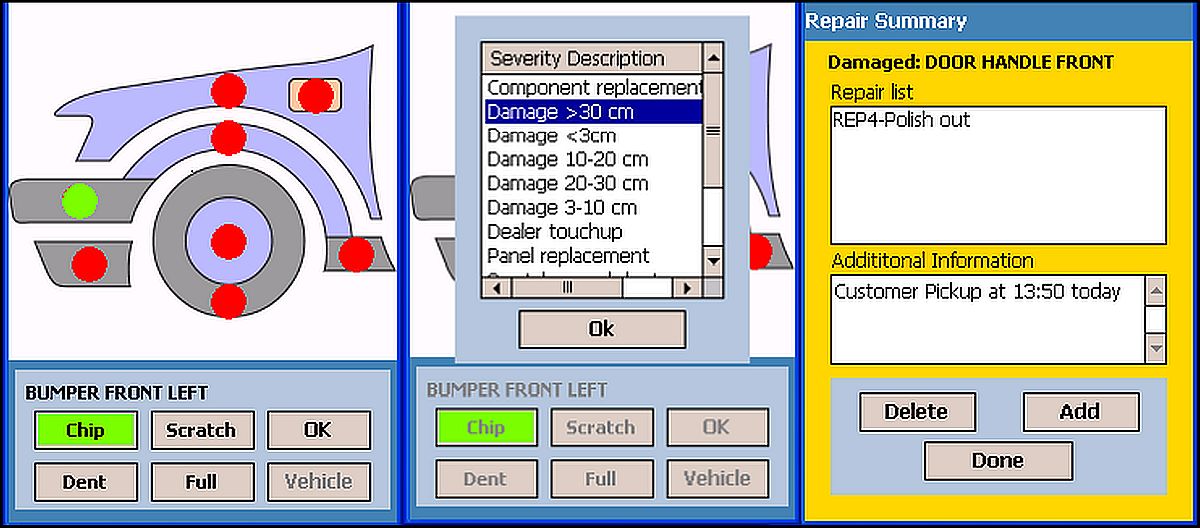

Three data entry screens showing how an inspector recorded damage to a front bumper and ordered a repair to a front door handle

Contract identification and vehicle inspection

- Inspectors register their location and the contract.

- Codetrack presents the contract profiles for the makes and models of vehicles to check.

- They scan a barcode to identify the next vehicle

- Then they follow the splats and automated forms Codetrack generates to guide the inspection.

- Finally they can print out a damage assessment document on a Bluetooth® wireless printer and fix it to the vehicle.

Automated data collection

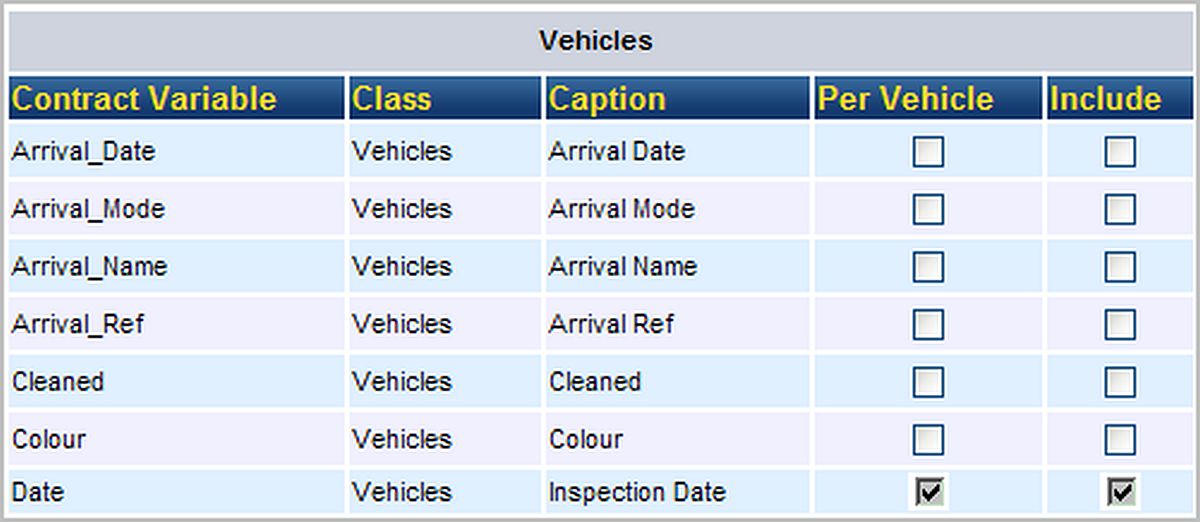

The software that generates the data collection forms is highly configurable. The company defined dozens of data collection variables relating to cars, routes, destinations, quality of vehicle handling at transport hubs, and much more.

Administrators can use the web portal to name new variables with simple checks, text boxes, drop-down lists and multiple-choice options. The company can reuse all the variables create new contracts with virtually endless variations / options. Insurers, logistics companies and manufacturers each have inspection forms tailored to their exact needs.

Contract variable configuration screens specify what data inspectors capture for a customer

“When customers come to us with new requirements, we can easily create automated inspection forms for them. It takes a matter of minutes to set up a contract compared to days previously,” noted the Operations Director. "For instance there was a storage facility that had a problem with contamination – we were able to simply insert a new field to check if metallic paint was being damaged as a result."

Synchronisation

When inspections are complete, the team put their devices in docking cradles to sync the database behind the web portal.

Data display and reports

The company and its customers can use any web browser to view their data. They can print off reports in a range of formats such as make and model of car. They can also select data to extract into a spreadsheet to integrate with their systems.

The Codeway project manager, Stuart Lucas, commented, “The web portal is the core, customer-facing part of the system. We did some complex work to give the customers freedom to view and use their data in any way. The automation of data capture and display delivers major competitive advantages.”

Device selection

After an initial deployment with other devices the company saw the benefits of top quality rugged handhelds.

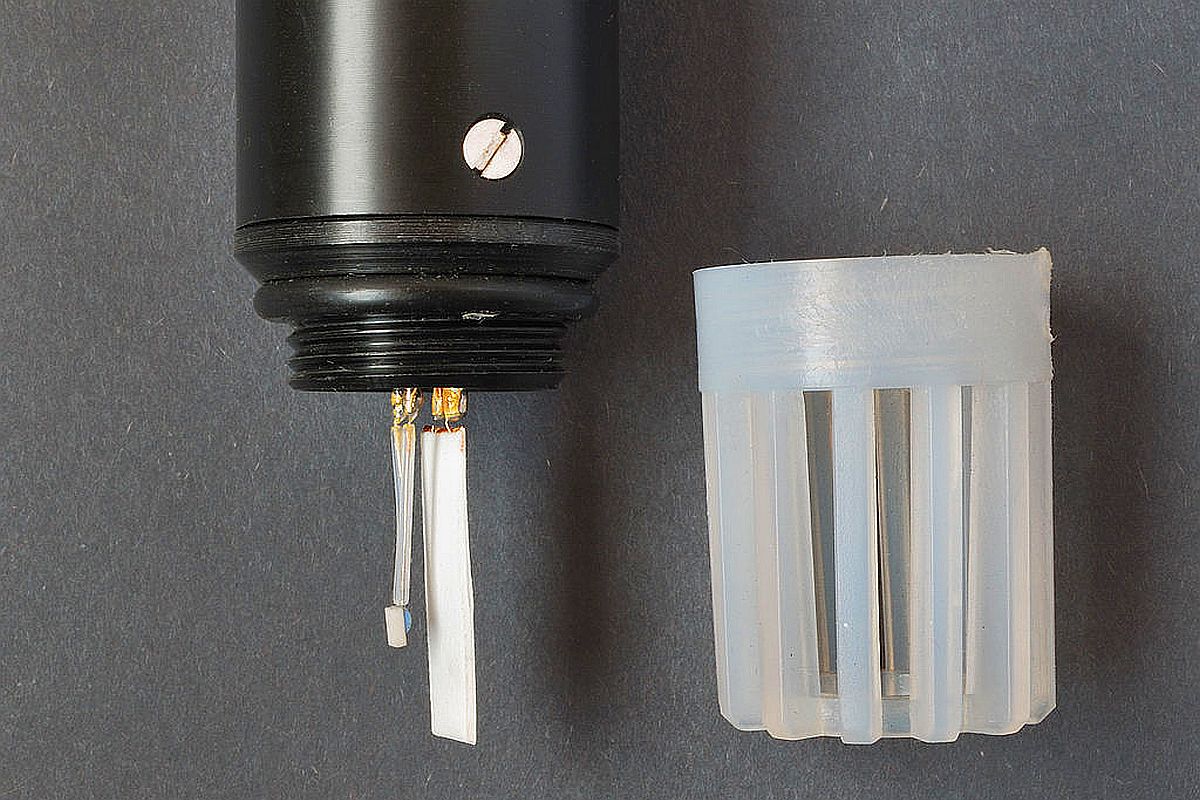

Again in the words of the Operations Director, “One of the problems with the initial device was that it couldn’t really cope with the worst of the weather and connection pins were corroding. After testing a range of alternatives we went for Motorola. The products are tough, robust and weatherproof. The scanner on the 9000 range is also the most accurate we’ve seen, overcoming depleted codes to deliver accurate readings. This is important as we scan bar codes on windscreens to identify each vehicle and the codes often fade in sunlight.”

Results

- The company has transformed its business.

- The infrastructure will support new commercial services to check the way sites are run and vehicles handled at ports.

- The company has detailed team performance measures for continuous improvement.

In summary the Operations Director said, "In four years we estimate the time and cost savings are approaching £1 million. We’ve differentiated our business, have the infrastructure to easily add more customers and inspect more vehicles. We’re delighted with the deployment.”