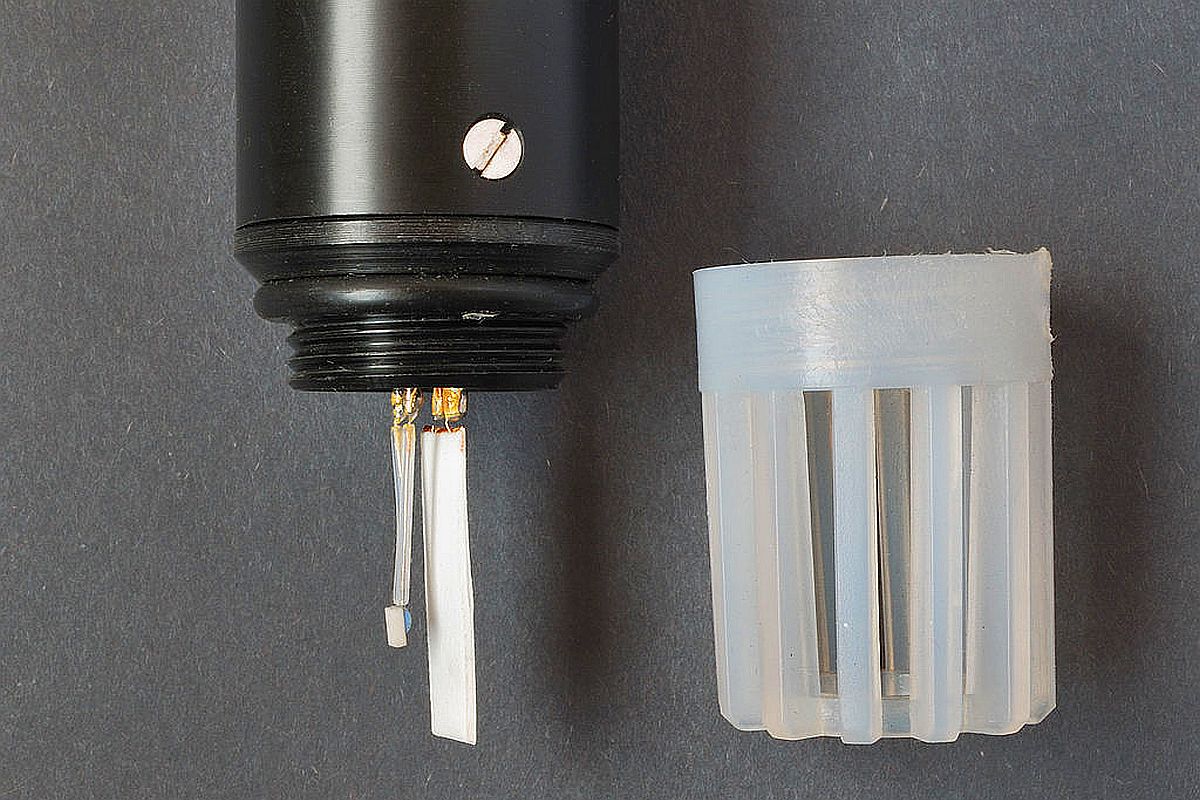

An image DNA genetic material [Image: Pixabay, Geralt]

A DNA company testing samples for hospitals and doctors was a victim of its own success. It was taking too long to process samples.

Abacklog of thousands of tests in progress was affecting cashflow.

Problem redefined

The company asked BellHawk to provide a scheduling system but the solution was a barcode tracking system.

They had a laboratory information management (LIM) system customised to their business needs. They believed this gave them accurate sample tracking data.

However many samples were not tracked for days or weeks. Typically these were forgotten in a freezer until someone came looking for them.

Solution

After discussions with BellHawk the company decided to install a BellHawk barcode tracking system. The LIM System provides data about sample containers to be tracked.

The BellHawk system uses the PCs installed throughout the labaoratories to access the LIM system. Equipped with barcode scanners they track bar coded vials, test tubes and the "96 well plates" containing the samples.

BellHawk uses this realtime data to track the physical location and process step of each container of samples.

Results

- Tracking reports enabled the company to identify and correct several major bottlenecks in the DNA processing flow.

- Real–time tracking data eliminated the missing sample problem.

- The company increased productivity by deploying technical staff to the laboratories with the heaviest workload.

- They reduced the time to process samples and improve cash flow by reducing their work–in–process backlog.

Related Applications

BellHawk Life-Science

Biotech Reagents